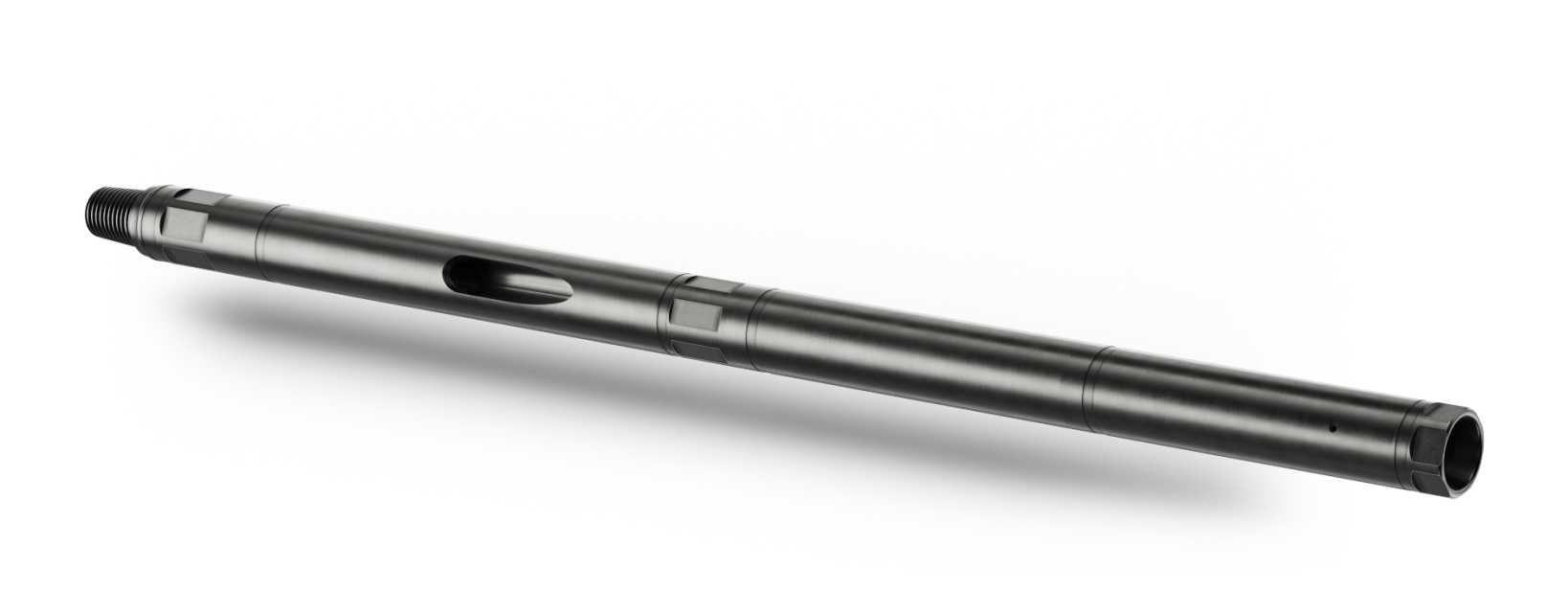

LiMAR® VENTURI JUNK BASKET

1st February 2022

To further enhance our existing suite of Coiled Tubing Tools and to meet our customer's needs, LiMAR® has developed and acceptance tested its first Venturi Junk Basket.

The LiMAR® Venturi Junk Basket provides optimum lift capabilities, enabling large debris to be removed from the well-bore, in situations where fluid velocities are insufficient or bottom hole pressure will not support returns to surface.

The tool has evolved over a period of time where extensive testing of various Jet Pump layouts have led to the final revision being released. As well as being extremely user friendly, the production version features an optimum configuration, which addresses the critical dimensions of all components affecting Jet Pump performance. Due to the mixing chamber dimensions varying to that of most readily available Venturi tools, the LiMAR® product features a reduced make up length to aid in situations where rig up height is limited

The critical dimensions from the 1-11/16" prototype tool, which has recently been tested and approved, will be applied across the range of tool sizes, with the larger tools, 2-7/8" and above, offering three separate mixing chambers.

This not only provides the best possible performance and ease of set up, but will allow the nozzle kits to be interchanged between tool sizes. In order to maximise flow rate and adhere to the area ratios required to increase performance, the tool has been developed to include a large mixing chamber diameter, which permits the use of a greater diameter orifice than offered in most equivalent tools. This in turn permits higher flow rates, through the CT string and Jet Pump, which produces increased velocity of suction flow and the potential to remove larger objects. During testing it was discovered that the 1-11/16" LiMAR® tool is capable of lifting a 1" diameter steel ball from a 1" stand-off at 35 gpm, and a back pressure of only 270 psi. Achieving this level of performance, with such a low pressure drop, clearly illustrates the efficiency of the tool design and provides encouragement on the potential of the tool at increased flow rates

Optional cages are available ranging from Flutters and Four Finger Cages to Check Valves, with the Flutters and Finger Cages featuring large internal diameters, to maximise the size of solids which can be removed from the well-bore. The tool is supplied with a 1000 micron filter as standard, which has been selected to ensure a maximum flow area with the ability to ensure debris is retained within the lower section of the tool. In applications where fine sands may need to be removed, screens with smaller slot widths are available.

The tool has been qualified for commercial use and available in 1-11/16", 2-1/8", 2-5/8", 2-7/8" and 3-1/8" sizes.

Download the product information sheet for more information or contact our sales team.