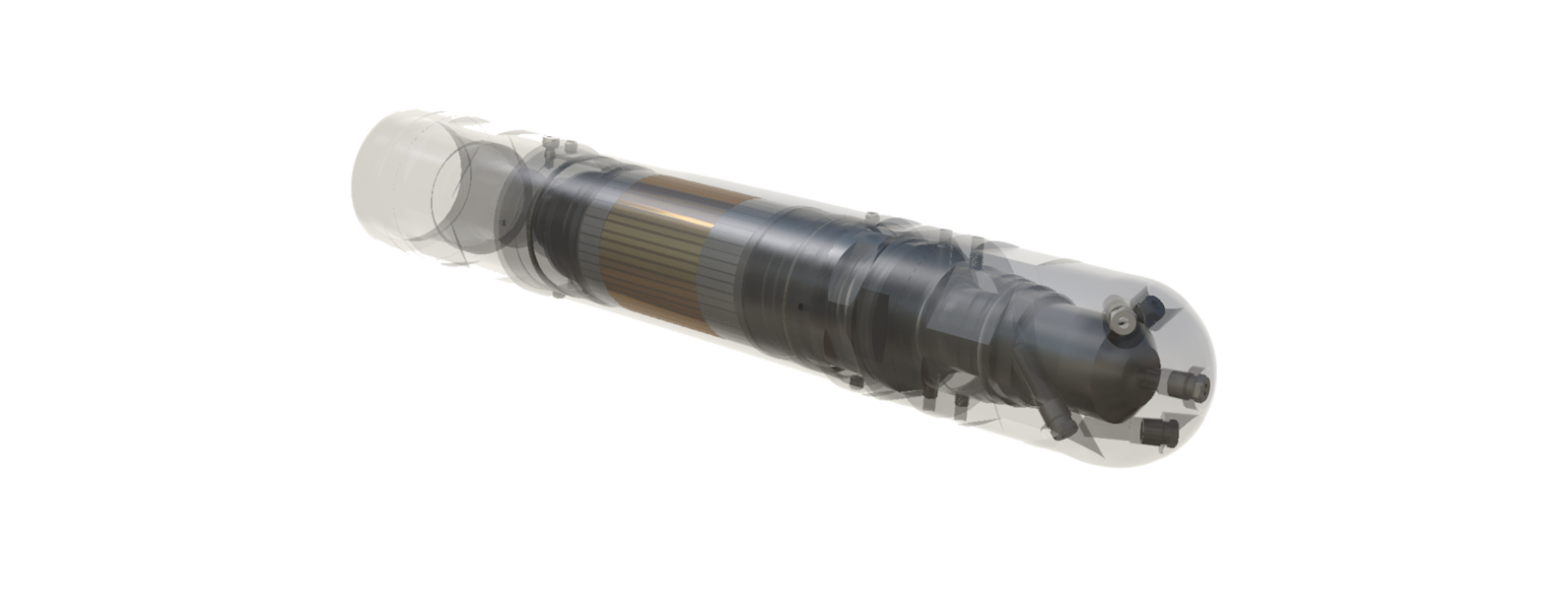

RELIABLE & EFFECTIVE - ROTARY JETTING TOOL

18th May 2016

The hydraulic brake system incorporated into the LiMAR product along with the temperature compensation system ensure a consistent rotational speed over a considerable temperature range.

By incorporating interchangeable hard wearing carbide nozzle inserts, a flow straightener to improve jet coherence and interchangeable rotating head sizes, the tool efficiently removes debris, paraffin waxes and scale build ups from the tubulars.

Standard sizes are supplied in 1.687”, 1.750”, 2.125”, 2.250”, 2.500” & 2.875 OD’s with customised Rotating nozzle heads available to suit customer requirements, reduce stand off and maximise jet impact pressure.

For further information on the Rotary Jetting Tool please contact our sales team.